What is a sewer pipe sleeve and how does it work?

In the world of plumbing and sewer systems, understanding the mechanisms can prevent costly repairs. A sewer pipe sleeve serves as a protective layer for damaged sewer pipes. This sleeve helps to reinforce the pipe structure and minimize leaks. According to industry expert Dr. Emily Tran, "A sewer pipe sleeve acts as a cost-effective solution to extend the life of aging sewer lines."

These sleeves are often made from durable materials, ensuring they withstand harsh conditions. They can be inserted easily into existing pipes, saving time and labor. However, many homeowners remain unaware of their benefits. Some believe that traditional repair methods are more effective. This misconception can lead to unnecessary expenses and prolonged issues.

The installation process is not without its challenges. Not all local regulations accommodate the use of sewer pipe sleeves, creating a gap in awareness. It is essential for professionals to educate communities about this option. Despite its advantages, not everyone recognizes the need for modern solutions, like sewer pipe sleeves, in managing aging infrastructure.

What is a Sewer Pipe Sleeve?

Sewer pipe sleeves are essential components in plumbing systems. They serve as protective coverings for existing pipes, ensuring they function properly. The sleeve acts as a barrier against corrosion and other forms of damage. This added protection can extend the lifespan of the pipes significantly.

When a sewer line faces leaks or damage, a sleeve can be used to repair it.

The process is often less invasive than traditional methods. However, not all pipes can benefit from sleeves. Some may require complete replacement. The effectiveness of a sleeve also depends on the installation quality. If poorly installed, it might lead to even larger issues down the line.

A sewer pipe sleeve typically consists of strong, durable materials designed to handle pressure. Installation usually requires professional expertise. Identifying pipe conditions beforehand can be tricky. Some may seem fine, yet hidden problems exist. Understanding these details is crucial for a successful repair.

Types of Sewer Pipe Sleeves and Their Applications

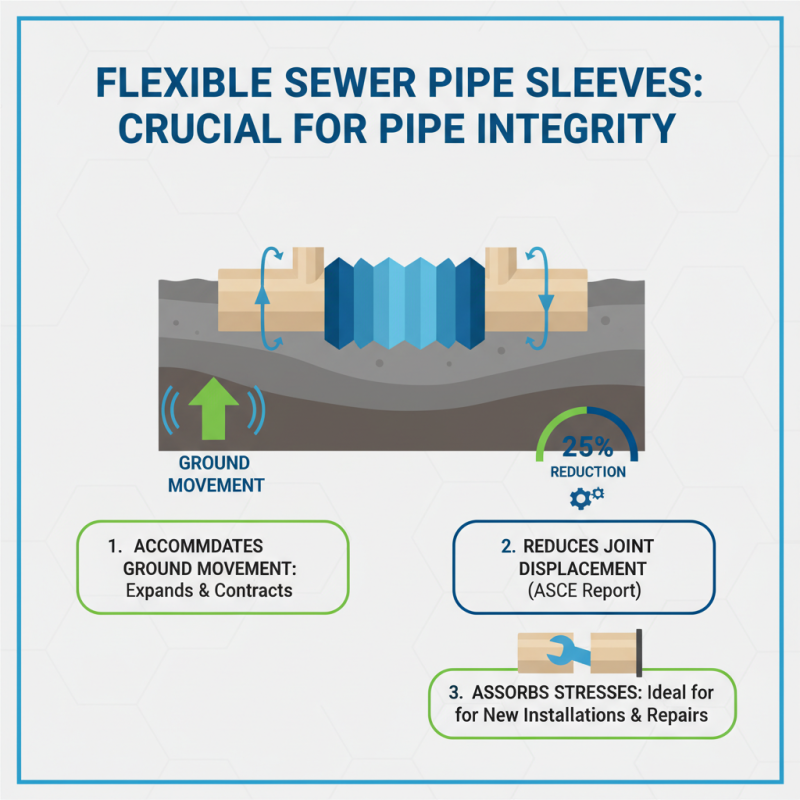

When considering sewer pipe sleeves, different types play crucial roles in various applications. One common type is the flexible sleeve. This type can expand and contract, accommodating ground movement. A report from the American Society of Civil Engineers indicated that flexible sleeves can reduce the risk of joint displacement by up to 25%. Their ability to absorb stresses makes them popular in new installations and repairs.

Rigid sleeves are another vital option. They provide structural support to damaged pipes. Rigid sleeves tend to be less flexible but offer added stability. Many engineers recommend them for older, fragile pipes. Data shows that using rigid sleeves can extend the lifespan of a sewer system by an average of 15 years under proper conditions.

However, not all installations go smoothly. Sometimes, improper fittings can lead to leaks. This oversight can create costly repairs later. Moreover, the choice of materials impacts longevity. Ensuring compatibility with existing pipes is crucial. There are many factors to consider when selecting a sleeve. Each application varies, and mistakes can mean more than just repairs.

How Sewer Pipe Sleeves Function in Plumbing Systems

Sewer pipe sleeves are essential components in plumbing systems. They protect pipes from corrosion and external damage. These sleeves help maintain the integrity of sewer lines. A well-maintained sewer system can improve the overall flow and efficiency of waste disposal.

According to industry reports, nearly 23% of sewer failures are due to pipe deterioration. Sleeves can extend the life of these pipes significantly. By reducing the risk of leaks, they minimize costly repairs. The added layer of protection creates a barrier against tree roots and ground shifts. This is crucial for urban areas where such issues are common.

However, not all installations are perfect. Misalignment during installation can lead to future problems. Regular inspections are necessary to ensure the sleeves function correctly. Skipping maintenance can result in serious plumbing issues. Inadequate attention to sewer sleeves may lead to increased costs over time. Thus, proactive care is vital in avoiding larger problems.

Installation Process of Sewer Pipe Sleeves

The installation process of sewer pipe sleeves involves several key steps, each requiring attention to detail. Begin by assessing the existing sewer pipe for any damages or blockages. Cleaning the area thoroughly is essential, as dirt and debris can compromise the sleeve's functionality. This step helps ensure a smooth installation.

After the preliminary checks, measure the length of the sewer pipe carefully. Cut the sleeve to the required length, ensuring it fits snugly. The installation can get tricky here. Sometimes, the sleeve may not align perfectly with the pipe, leading to potential leaks. Using a sealant on the edges can help avoid this issue. Secure the sleeve using clamps to prevent any movement during operation.

Next, reconnect the sewer pipe to the main system. Monitor for any signs of leakages after installation. This is critical but often overlooked. Many assume that once it’s in place, that’s the end. It’s advisable to conduct routine checks. Over time, pipes can shift, or degradation may go unnoticed. Regular inspections can save significant repair costs down the line.

Sewer Pipe Sleeve Installation Process

This bar chart illustrates the estimated time required for each stage of the sewer pipe sleeve installation process. The stages include Preparation, Installation, Testing, and Backfilling, with varying hours needed for completion.

Maintenance and Considerations for Sewer Pipe Sleeves

Sewer pipe sleeves play a crucial role in maintaining the integrity of sewer systems. These sleeves serve as protective layers around existing pipes. They help prevent leaks and protect the pipes from external damage. Over time, however, wear and tear can affect sleeve effectiveness. It's essential to conduct regular inspections to identify any potential issues.

Maintaining sewer pipe sleeves requires careful attention. Regular cleaning helps prevent blockages caused by debris. Keeping an eye on any corrosion or cracks is also necessary. In some cases, it might be wise to replace the sleeve entirely. Deterioration can lead to bigger problems down the line. Noticing the small signs early can save considerable time and costs later on.

Landowners often overlook sewer maintenance. Many think their pipes are perfectly fine until it's too late. Scheduling routine inspections can reveal hidden problems. It’s better to address small issues now than face major repairs in the future. Even minor damage can escalate quickly if neglected. Proper care and maintenance of sewer pipe sleeves are vital for system longevity.

What is a sewer pipe sleeve and how does it work? - Maintenance and Considerations for Sewer Pipe Sleeves

| Dimension | Description |

|---|---|

| Material | Typically made from PVC, polyethylene, or metal |

| Function | Adds structural support and prevents corrosion |

| Installation | Installed around existing pipes to enhance durability |

| Maintenance Frequency | Recommended every 3-5 years depending on environment |

| Common Issues | Cracks, leaks, and build-up of debris |

| Benefits | Improved flow, longevity, and reduced pollution risk |

Related Posts

-

Creative Applications of Sewer Pipe Sleeve Repair Techniques

-

7 Essential Tips for Effective Home Sewer Line Repair You Can't Ignore

-

Understanding Sewer Line Relining: A Comprehensive Guide to Modern Pipeline Repair Techniques

-

Unlocking the Benefits of Sleeve Sewer Line Technology for Efficient Waste Management

-

Essential Guide to Understanding Main Sewer Line Repair: What Homeowners Need to Know

-

Understanding the Importance of Regular Home Sewer Line Maintenance for Lasting Repair Solutions