Top Tips for Pump Repair in 2026 What You Need to Know?

In the ever-evolving landscape of pump repair, understanding the latest trends and technologies is crucial. According to a report from the Global Pump Association, the pump repair market is expected to grow by 8% annually through 2026. These insights highlight the increasing need for effective maintenance and repair strategies in the industry.

Expert James L. Montgomery, a well-known figure in pump repair, states, "Preventive maintenance can significantly reduce downtime and costs." His words resonate with many in the field, emphasizing the importance of proactive measures. As techniques advance, the focus on efficient repair processes and sustainable practices becomes paramount.

However, it's important to acknowledge that challenges remain. Many professionals still face skill gaps and outdated equipment. Addressing these issues is vital for improving pump repair outcomes. An informed approach will ensure smoother operations and extend the lifespan of pumps in various sectors.

Essential Tools and Equipment for Pump Repair in 2026

When it comes to pump repair, having the right tools is crucial. In 2026, certain essential equipment stands out as a necessity. A high-quality wrench set should be at the top of your list. Choose adjustable wrenches for versatility. They help secure various nuts and bolts. A torque wrench also becomes important for precision. It ensures proper tightening without damaging components.

Additionally, invest in a reliable multimeter. This tool is invaluable for diagnosing electrical issues in pumps. You may also find a pipe cutter useful if you need to replace sections of piping. Safety gear should not be overlooked. Gloves and goggles protect against unexpected leaks and debris. When working on older models, be mindful of rust and corrosion. This can complicate repairs and lead to further damage.

You might experience frustration with difficult fittings. Sometimes, parts may not fit as expected. Be prepared for trial and error. It's common to encounter unexpected hurdles during repairs. Each situation presents a chance to learn. Embrace the mistakes. They often teach essential lessons about maintenance and functionality.

Common Pump Issues and Troubleshooting Techniques

Pump issues can cause significant downtime and financial loss. According to industry reports, up to 30% of pumps fail due to inadequate maintenance. Common problems include seal leaks, cavitation, and abnormal vibrations. Identifying these issues early can save time and costs.

For seal leaks, it's essential to check seals regularly. Worn or damaged seals can lead to fluid loss and environmental hazards. Regular inspections can reduce the risk.

Cavitation occurs when vapor bubbles form within the pump and collapse. This can severely damage the equipment. Engineers should monitor flow rates and make adjustments as necessary.

Vibrations are another critical issue. Excessive vibrations can indicate alignment problems or imbalanced components. Symptoms include increased noise and operational instability. Use vibration analysis tools to gauge pump performance. Data trends can reveal underlying problems before they escalate. Using these troubleshooting techniques helps in making informed decisions. Regularly reviewing pump health can lead to an unexpected insight into operational efficiency.

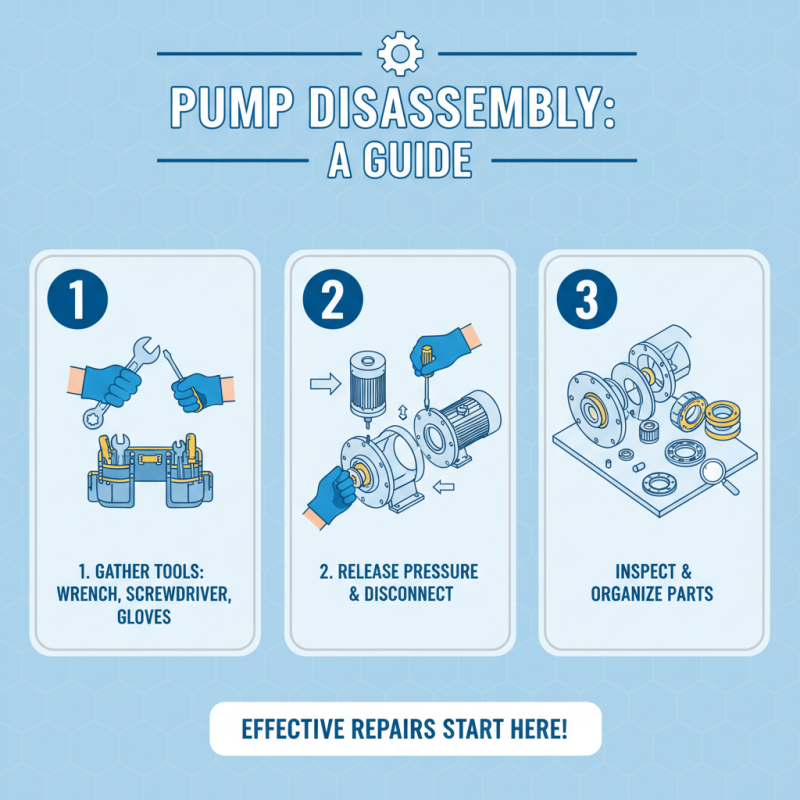

Step-by-Step Guide to Disassembling a Pump

Disassembling a pump can be daunting. However, understanding the process will help you achieve effective repairs. Before you begin, make sure you have the right tools: a wrench, screwdriver, and safety gloves.

Start by disconnecting the power source. Safety first! Afterward, drain any remaining fluid from the pump. This step is crucial to avoid spills and injuries. Take your time during this process. Rushing may lead to mistakes.

Carefully remove the pump casing. Some bolts may be stubborn. Use penetrating oil to ease the process. Keep track of all components as you disassemble. A disorganized workspace can lead to missing parts later. According to industry reports, nearly 30% of pump failures result from improper reassembly.

Tips: Document each step with photos. This habit helps in reassembling the pump correctly. Also, label parts clearly. An organized approach saves time and reduces frustration.

As you work through disassembly, don’t overlook the inspection of internal parts. Wear and tear may not be obvious. Check seals and bearings carefully. They are often the bits that need replacement. Remember, a meticulous approach can greatly enhance pump longevity.

Reassembling Your Pump: Best Practices

Reassembling a pump requires careful attention to detail. It’s vital to start with a clean workspace. Gather all parts and tools beforehand. Inspect each component for wear or damage. A close examination can prevent future issues. Missing or broken parts can lead to inefficient operation.

During assembly, follow the manufacturer’s guidelines closely. Pay attention to the orientation of seals and gaskets. These small elements play a significant role in preventing leaks. If you're unsure, double-check the configuration. Avoid forcing parts together, as it can cause misalignment. This could result in costly repairs later.

After reassembly, conduct a thorough inspection before powering the pump. Look for any signs of improper alignment. Small deviations can lead to serious problems. Test the pump under conditions similar to normal operation. If something seems off, it’s crucial to address it immediately. Remember, sometimes shortcuts can lead to longer-term issues. Taking time to do it right is worth the effort.

Top Tips for Pump Repair in 2026 What You Need to Know? - Reassembling Your Pump: Best Practices

| Tip Number | Best Practice | Description | Importance Level |

|---|---|---|---|

| 1 | Gather Necessary Tools | Ensure all repair tools and equipment are ready before starting the reassembly. | High |

| 2 | Clean All Components | Thoroughly clean all parts to prevent contamination during reassembly. | Medium |

| 3 | Inspect for Wear and Damage | Check each component for signs of wear or damage and replace if necessary. | High |

| 4 | Follow Manufacturer Guidelines | Adhere to specific instructions and torque settings when reassembling. | High |

| 5 | Lubricate Moving Parts | Use appropriate lubricants to ensure smooth operation of moving parts. | Medium |

| 6 | Test the System | Conduct a thorough test run to check for leaks or unusual noises. | High |

Preventive Maintenance Tips for Long-Lasting Pump Performance

In 2026, preventive maintenance remains crucial for pump performance.

Regular inspections help detect issues early. The U.S. Department of Energy reports that

up to 40% of equipment failure results from neglecting maintenance. Simple tasks, like

checking seals and lubricating bearings, can extend your pump's life significantly.

Many facilities overlook minor leaks. These leaks

can lead to larger problems down the line. According to industry studies, a leak as small as

0.1 gallons per minute can waste over 100,000 gallons annually.

Addressing these small issues can yield substantial savings and ensure efficient operation.

Training staff on routine checks is essential. A skilled team can identify unusual sounds or vibrations.

Not everyone is trained to notice these signs. Implementing checklists can help. However, relying

solely on technology isn’t enough. Human oversight

brings valuable insights that data alone may miss. Regular meetings to discuss maintenance practices

can foster a culture of care, yet many organizations still struggle with compliance.

This highlights the need for ongoing training and commitment to maintenance.

Related Posts

-

Comprehensive Pump Repair Checklist for Efficient Plant Operations and Reduced Downtime

-

2025 Top Tips for Effective Pump Repair: Common Issues and Solutions

-

How to Identify Common Symptoms of Pump Issues Before Calling for Repair

-

What is Pump Repair and How Can It Benefit Your Equipment?

-

10 Essential Tips to Repair Your Sewer Quickly and Effectively

-

How to Successfully Perform No Dig Pipe Repair for Lasting Results