2026 How to Effectively Perform Sewer Pipe Sleeve Repair Techniques?

Sewer pipe sleeve repair is a crucial technique in maintaining the integrity of our wastewater systems. Renowned expert John Smith emphasizes, "Proper sleeve repair can extend a pipe's lifespan significantly." This statement highlights the importance of effective repair methods.

In urban areas, aging sewer systems face constant pressure. Cracks and leaks can lead to serious environmental issues. Ignoring these problems could result in costly damage. Understanding the various sleeve repair techniques is essential for any contractor.

While models and techniques are available, real-world application often reveals flaws. Sometimes, installations might not hold up against natural elements. It's vital to continuously evaluate repair methods. Adapting to new challenges in sewer pipe sleeve repair ensures systems remain functional and reliable.

Understanding Sewer Pipe Sleeve Repair Technologies

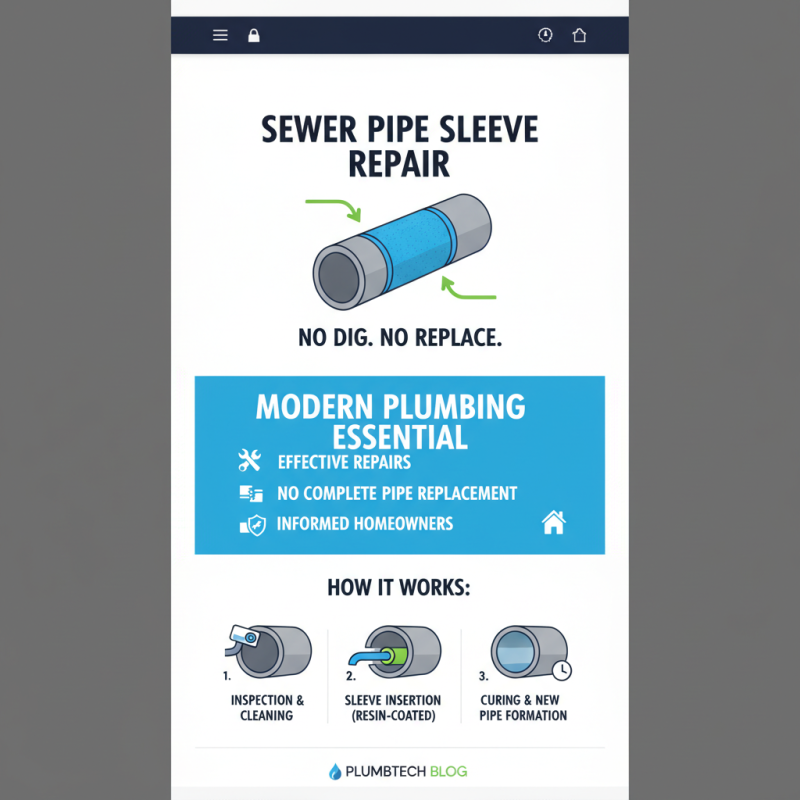

Sewer pipe sleeve repair technologies are becoming essential in modern plumbing. These methods allow for effective repairs without complete pipe replacement. Understanding how these techniques work can help homeowners make informed decisions.

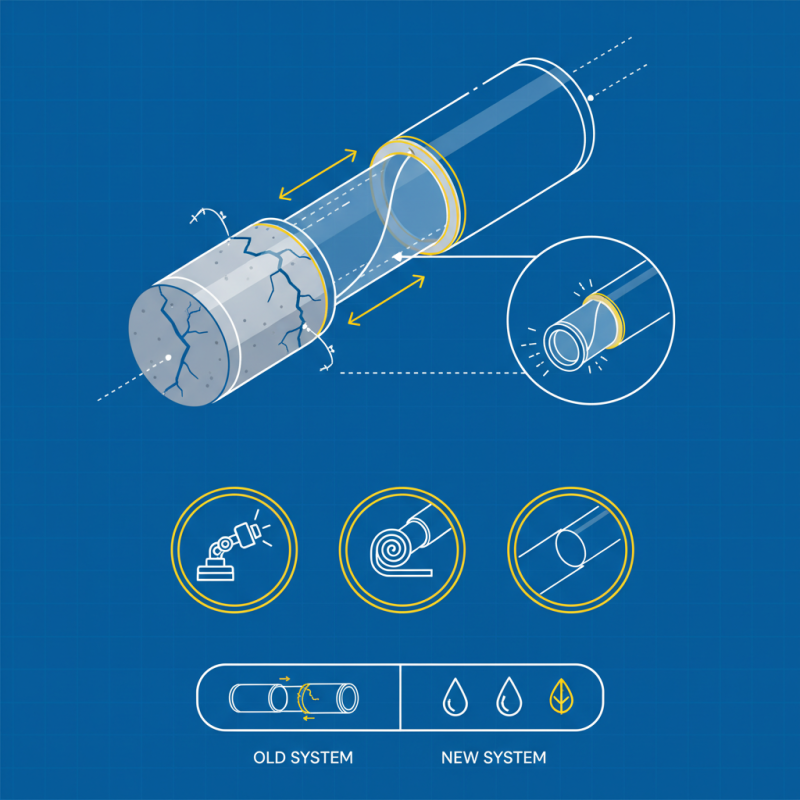

One popular method involves using a flexible sleeve. This sleeve is inserted into the damaged pipe. Once in place, it expands and hardens, creating a new inner surface. This process can be completed quickly, often in a single day. However, not all damages are suitable for this repair. Some might require additional assessments.

Another advanced technique employs resin infusion. In this method, a special resin is applied to a liner that is inserted into the pipe. The resin then hardens, sealing off leaks and cracks. While this method is effective, it requires precise application. Mistakes in this process can lead to incomplete repairs and future issues. Understanding these technologies helps in weighing the benefits and concerns before opting for a repair.

Essential Tools and Materials for Sleeve Repair of Sewer Pipes

When performing a sewer pipe sleeve repair, having the right tools and materials is crucial. A pipe cutter helps to remove damaged sections of the pipe cleanly. A measuring tape ensures accurate lengths for the sleeve. Choose a durable sleeve that fits your pipe size. Quality adhesive is also important; it ensures a tight, lasting seal.

A rubber gasket can enhance your repair, creating a watertight fit. Don’t overlook safety gear. Gloves protect your hands, while safety glasses shield your eyes from debris. A sturdy ladder may be needed, especially in deep installations.

Be prepared for unexpected issues. You might encounter stubborn rust or corrosion. In such cases, additional tools like wire brushes come in handy. Make sure to have all materials ready before starting; running back and forth can disrupt your workflow. Remember, effective repairs take time and patience.

2026 Sewer Pipe Sleeve Repair Techniques: Essential Tools and Materials

Step-by-Step Process for Effective Sewer Pipe Sleeve Installation

Sewer pipe sleeve installation is a crucial technique for effective repairs. This method helps restore the integrity of damaged pipes without extensive excavation. According to industry data, using sleeve technology can cut repair time by up to 50%.

To begin, the area around the damaged pipe must be excavated. This process allows for access to the sewer line. During excavation, care is required to avoid damaging surrounding soil or objects. Next, a clean and thorough inspection of the pipe is essential. Any residual debris or moisture can impede the sleeve’s effectiveness.

Once the pipe is ready, the sleeve is carefully inserted. Technicians may use specific tools to ensure proper fitting. It is important to monitor the installation for any misalignment. Research indicates that misalignment is a common issue in 20% of installations. After insertion, a curing process begins. The conditions during curing must be controlled; humidity and temperature significantly affect solidification times.

2026 How to Effectively Perform Sewer Pipe Sleeve Repair Techniques? - Step-by-Step Process for Effective Sewer Pipe Sleeve Installation

| Step | Description | Tools Required | Estimated Time | Cost Estimate |

|---|---|---|---|---|

| 1 | Assess the Damage | Inspection camera | 1 hour | $100 |

| 2 | Prepare the Sleeve | Sewer sleeve, adhesive | 30 minutes | $150 |

| 3 | Insert the Sleeve | Pulling tools | 1 hour | $200 |

| 4 | Seal the Ends | Sealant | 30 minutes | $50 |

| 5 | Conduct Final Inspection | Inspection camera | 1 hour | $100 |

Common Challenges and Solutions in Sewer Pipe Sleeve Repairs

Sewer pipe sleeve repairs often face various challenges. One significant issue is material compatibility. Many repair techniques rely on specific materials that may not bond well with existing pipes. This can lead to failures. A report from the American Society of Civil Engineers highlights that about 30% of repairs fail due to material mismatch. It's critical to assess existing infrastructure before choosing repair materials.

Another challenge is accurate pipe inspection. Without thorough assessments, repairs may overlook underlying issues. According to industry studies, up to 25% of sewer inspections miss critical defects. Unseen cracks or blockages can compromise repair efforts. Inspecting pipes using advanced technologies can mitigate this risk.

Lastly, installation difficulties can arise. Proper alignment during sleeve installation is crucial. A misalignment can cause leaks, leading to costly repairs. Research shows that nearly 20% of sleeve installations require rework due to alignment errors. Training for technicians can reduce these instances and improve overall effectiveness. Addressing these common problems is essential for successful sewer pipe sleeve repair projects.

Maintenance Tips Post-Sewer Pipe Sleeve Repair for Longevity

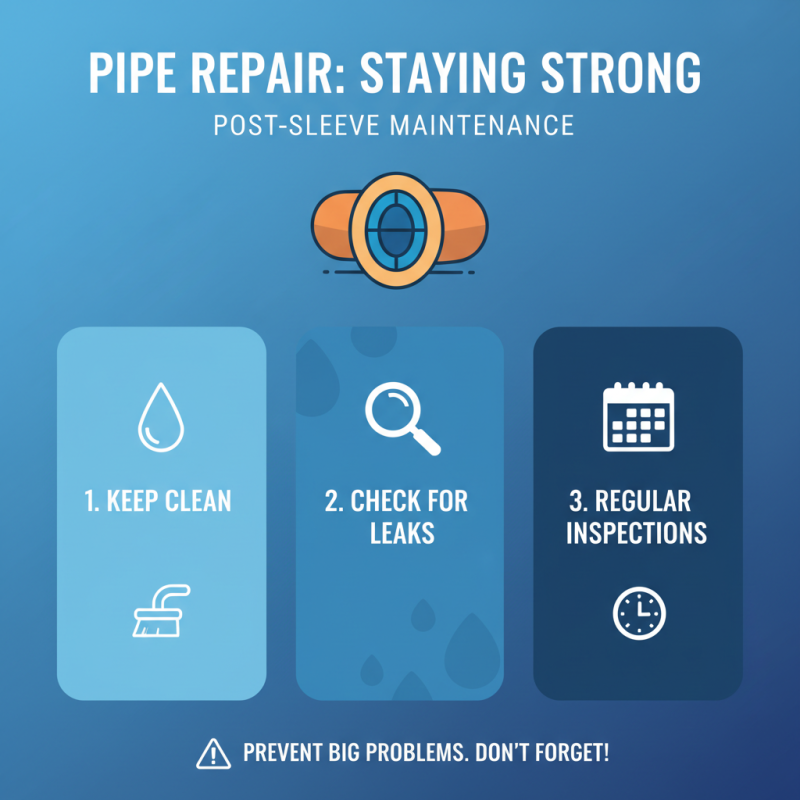

Post-sewer pipe sleeve repair maintenance is crucial for longevity. Many people forget this step. Keeping the repaired area clean is essential. Regularly check for any signs of leakage. Small leaks can develop over time. Any unnoticed leak will lead to bigger issues. Inspect the pipes every few months.

Applying a protective sealant can help. This reduces the likelihood of corrosion or damage. Ensure the area remains free from debris. Plants or roots may intrude into the pipes again. Watch for smells or unusual sounds. These could signal underlying problems.

Routine maintenance can be a challenge. It requires diligence and effort. Some homeowners may overlook it. Educating yourself is key. Use a checklist if needed. Document findings during inspections. It helps track changes over time. Ultimately, the goal is to maintain the integrity of the repair.

Related Posts

-

Creative Applications of Sewer Pipe Sleeve Repair Techniques

-

7 Essential Tips for Effective Home Sewer Line Repair You Can't Ignore

-

7 Essential Tips for Effective Sewer Pipe Sleeve Repair Techniques

-

Understanding Sewer Line Relining: A Comprehensive Guide to Modern Pipeline Repair Techniques

-

Unlocking the Benefits of Sleeve Sewer Line Technology for Efficient Waste Management

-

Essential Guide to Understanding Main Sewer Line Repair: What Homeowners Need to Know