How to Perform No Dig Sewer Pipe Repair Effectively?

No dig sewer pipe repair is a revolutionary technique in plumbing. It allows homeowners to fix damaged pipes without extensive excavation. This approach minimizes disruption to your property and surrounding landscape.

Many people underestimate the complexity of sewer repairs. Traditional methods can cause significant damage and mess. Learning about no dig sewer pipe repair equips you with a more efficient solution. It’s essential to be aware of the equipment and techniques involved.

While this method is effective, it requires careful planning. Improper execution may lead to future issues and costly repairs. Embracing this technology can save time, money, and headaches in the long run. Understanding its nuances will help you make informed decisions.

Understanding No Dig Sewer Pipe Repair: An Overview

No dig sewer pipe repair is an innovative approach to fixing damaged pipes without digging up your yard. This method uses advanced technology to solve problems buried underground. It significantly reduces disruption and preserves landscaping. The process often involves relining existing pipes or inserting new ones without major excavation.

Understanding the benefits of no dig repair is crucial. Traditional methods can be costly and time-consuming. A quick fix may seem tempting, but rushing could lead to future issues. The technology used in no dig repairs is constantly evolving, but it isn't always perfect. Sometimes, it might not reach every damaged section. Proper assessment is key.

While no dig methods can be effective, an expert evaluation is necessary. DIY attempts can lead to complications. Understanding the specific needs of your sewer system is vital. Ensuring the right tools are used can influence the outcome. It's worth considering all options before making a decision.

Essential Tools and Materials Needed for No Dig Repair

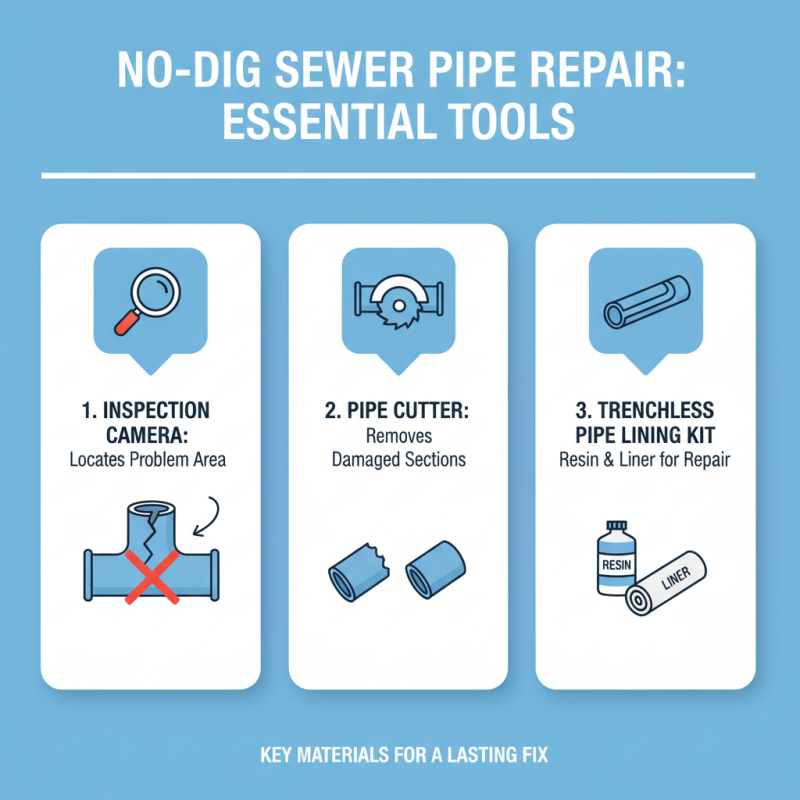

When performing a no dig sewer pipe repair, having the right tools and materials is crucial. A high-quality inspection camera helps locate the problem area. A pipe cutter makes cutting damaged sections easier. You’ll also need a trenchless pipe lining kit. This kit often includes the resin and liner required for the repair.

Don't forget personal protective equipment. Gloves and safety glasses protect you from debris and chemicals. A vacuum or pump may be necessary to handle any excess water in the line. You might face unexpected challenges, such as stubborn blockages. Be ready for some trial and error.

A good repair requires careful planning. Sketch out the layout of your pipes. Take notes on the condition of existing infrastructure. Remember, rushing can lead to mistakes. Reflect on previous repairs for insights. Learning from each project helps improve your skills.

Step-by-Step Process for Performing No Dig Sewer Pipe Repair

No dig sewer pipe repair is a great solution to damaged pipes. This method minimizes excavation. It’s less disruptive compared to traditional methods. You can complete this process more quickly, saving time and money.

Start by assessing the damage. Use a camera to inspect the pipe. Identify cracks, blockages, or tree roots. This step is crucial. You want to know the exact problem before you begin.

Next, prepare the area. Clear away any debris. Gather all necessary tools and materials. This includes resin and a relining tube. Once you’re ready, begin inserting the relining tube into the existing pipe. Inflate it with air to ensure a tight fit.

Allow the resin to cure. This may take some time. Be patient during this phase. After curing, check for leaks. You want to be thorough. Although this method is effective, not every job will be perfect. Some areas may require additional focus or second attempts. Always reflect on your work for future improvements.

How No Dig Sewer Pipe Repair Saves Time and Cost

Common Challenges and Solutions in No Dig Sewer Repairs

No dig sewer repairs offer a modern solution to traditional pipe issues. However, these methods face unique challenges. A report by the Trenchless Technology Center indicates that over 25% of trenchless projects encounter unexpected ground conditions. Soil type, groundwater levels, and existing infrastructure can complicate repairs. The variability of underground conditions often leads to project delays, increasing costs and frustration.

Another common challenge is the assessment of existing pipelines. A 2022 study revealed that improper inspection techniques can result in misdiagnosis. Unexpected blockages or damage may surface during repairs. This oversight can lead to significant delays. Technicians must employ advanced imaging technologies. High-resolution cameras and sonar equipment can provide a clearer picture of pipe conditions.

Despite these hurdles, no dig repairs can significantly reduce surface disruption. The environment endures less disturbance than traditional methods. However, as projects progress, specialists occasionally encounter unforeseen issues. Contractors must remain adaptable and informed. Training and continuous education can mitigate many problems during execution. Adaptability and proactive planning are crucial for successful no dig sewer repairs.

Maintenance Tips After No Dig Sewer Pipe Repair Completion

After completing a no dig sewer pipe repair, proper maintenance is crucial. Studies show that about 30% of sewer lines can face issues within two years if not properly maintained. Regular inspections help in identifying potential problems early. Schedule these if possible. Check for signs of clogging or leaks. Remember, even newly repaired lines can have weaknesses.

Another vital maintenance tip is monitoring water flow. A significant change in flow rate can indicate blockages. Flushing your system with clean water can help clear minor debris. Over time, small build-ups can become severe issues, sometimes leading to expensive repairs. Consider using environmentally friendly cleaners to avoid damage to the pipes.

Moreover, keep an eye on your landscaping. Tree roots can infiltrate seams, even in relined pipes. Preventive measures, like root barriers, can be effective. Engage with professional arborists to evaluate your trees’ proximity to the sewer lines. Always document any maintenance work done on your sewer system. This record can provide insight into recurring issues over time. Neglecting these details may lead to a cycle of repairs. A proactive approach helps extend the lifespan of your sewer lines significantly.

How to Perform No Dig Sewer Pipe Repair Effectively? - Maintenance Tips After No Dig Sewer Pipe Repair Completion

| Maintenance Task | Frequency | Duration (minutes) | Recommended Tools | Notes |

|---|---|---|---|---|

| Visual Inspection | Monthly | 10 | Flashlight, Camera | Check for any visible signs of damage or leaks |

| Hydrostatic Testing | Yearly | 30 | Pressure Gauge, Water Source | Ensure there are no leaks in the system |

| Clean Out Access Points | Bi-Monthly | 15 | Scoop, Gloves | Remove debris to maintain clear access |

| Camera Inspection | Every 2 Years | 60 | Sewer Camera, Monitor | Identify blockages or structural issues |

| Documentation Review | Yearly | 20 | Records, Notepad | Ensure all repairs and maintenance are documented |

Related Posts

-

Innovative Approaches to Sewer Repair Without Digging A Comparative Analysis of Efficiency and Cost

-

How to Use Trenchless Technology for Effective Sewer Repair Solutions

-

How to Effectively Address Sewer Issues with No-Dig Solutions

-

Revolutionizing Sewer Line Repair Techniques Without the Need for Digging

-

How to Successfully Navigate the Sewer Line Relining Process: A Complete Guide

-

Creative Options for Sewer Repair Without Digging Methods You Should Consider